First Africa Energy Technologies

FAET GABON LTD is a Joint Venture between Drill-Watt at 80% and stakeholders for 20%. FAET was founded in April 2021 by former SLB employees. Team brings close to 30 years experience in Oil & Gaz services. In Nov 2021 FAET acquired Baker Hughes cementing & pumping assets in Gabon

Delivering Quality Service to Meet Technical Goals

Our commitment to delivering quality service is at the heart of our mission to meet and exceed technical goals for cementing and pumping solutions in Gabon. By investing in local talent, advanced technology, and a deep understanding of Gabon’s unique geological and industrial landscape, we aim to become the foremost local provider. Our focus is on delivering dependable, high-performance services tailored to the specific needs of our clients, ensuring sustainable growth and unparalleled expertise within Gabon’s energy sector. Our vision is to lead as the first and best local content cementing and pumping services provider, setting new standards for quality, efficiency, and reliability. »

FAET Gabon – Basic presentation

- FAET GABON LTD is a Joint Venture between Drill-Watt at 80% and stakeholders for 20%.

- FAET was founded in April 2021 by former SLB employees. Team brings close to 30 years experience in O&G services.

- In Nov 2021 FAET acquired Baker Hughes cementing & pumping assets in Gabon

- Our aim is to be the best local Energy service company, starting with Cementing.

- We promote a culture of diversity and seek top performers to meet clients expectations with strong emphasis on Service Quality, HSE & Compliance Culture.

- Operations experience in Sub-Saharan Africa, USA, North Sea, Europe and Middle-East.

- We just completed a spotless cementing campaign in Zimbabwe (2 wells) for Invictus Energy Ltd under Baker as partner where they provided mud & chemicals and FAET dealing with Cementing equipment and personnel, including Lab & Testing.

- In Congo Rep, we have equipment and personnel for a new project for 4 years, always with Baker as a partner.

Oilfield Services

Cementing Experience >20 years

• Strong Service Quality, HSE & Compliance culture and track record

• Direct field operations execution experience in Cementing Services

• Cementing job Supervisor, Field Engineer, Technical Engineer and DESC

• Cementing Field Services Manager & Operations Manager

• Primary Cementing, remedial Cementing and downhole tools

• Operations in Sub-Sahara Africa, North Sea, Europe, Middle-East

• Land, swamp, offshore, deep water & ultra deep water

General Oilfield Experience 30 years

• Full cycle OFS experience

• Global responsibility for service delivery, customer support and satisfaction for major customers @ HQ level

• HSE Leadership experience as HSE Leader

• Project management for Integrated Services

• Eastern Hemisphere Sales and Commercial Manager

• Executive Directorship and Board Membership of a large indigenous oilfield service company in West Africa

• Global Customer Accounts Management and Support

Core business overview

Primary cementing, onshore & offshore

▪ Remedial cementing

▪ Down Hole Tools operations

▪ Remote operations management

▪ Deepwater technical and operational expertise

▪ Equipment rental and Assets management

▪ Drilling and workover operations

▪ Technical assistance & assurance

▪ Personnel placement

▪ Pumping services

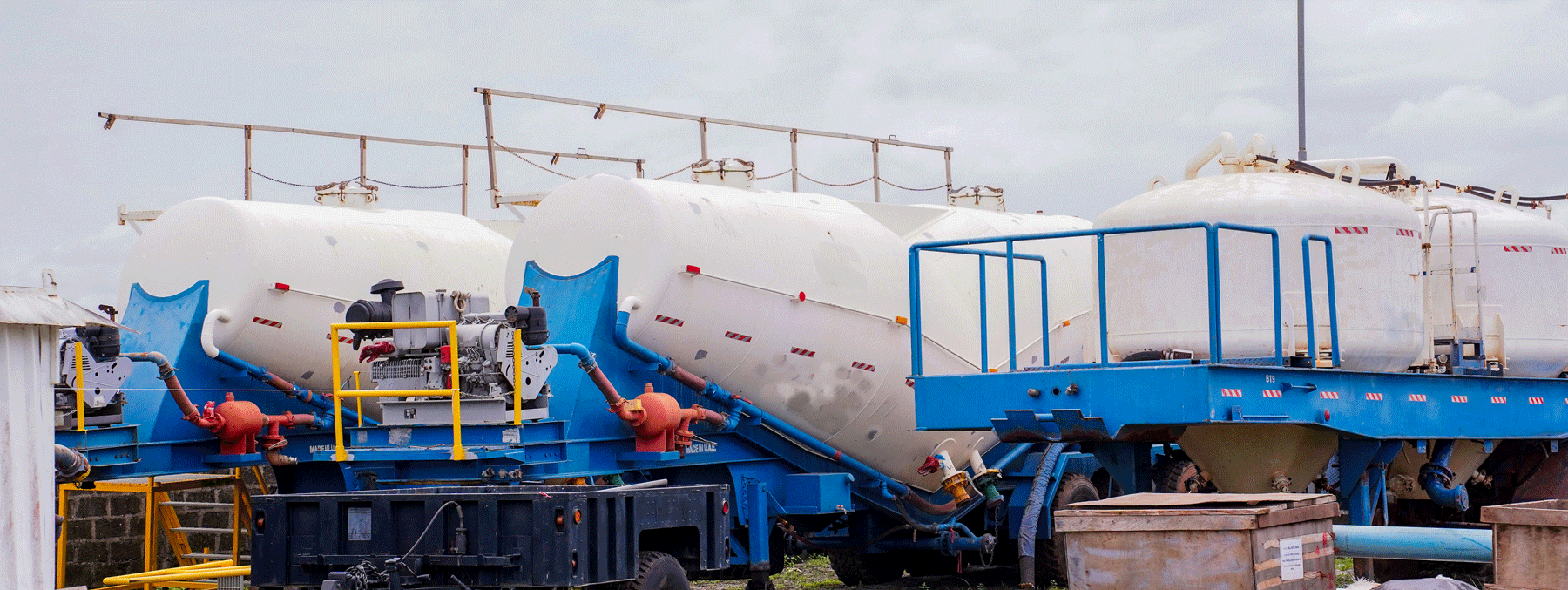

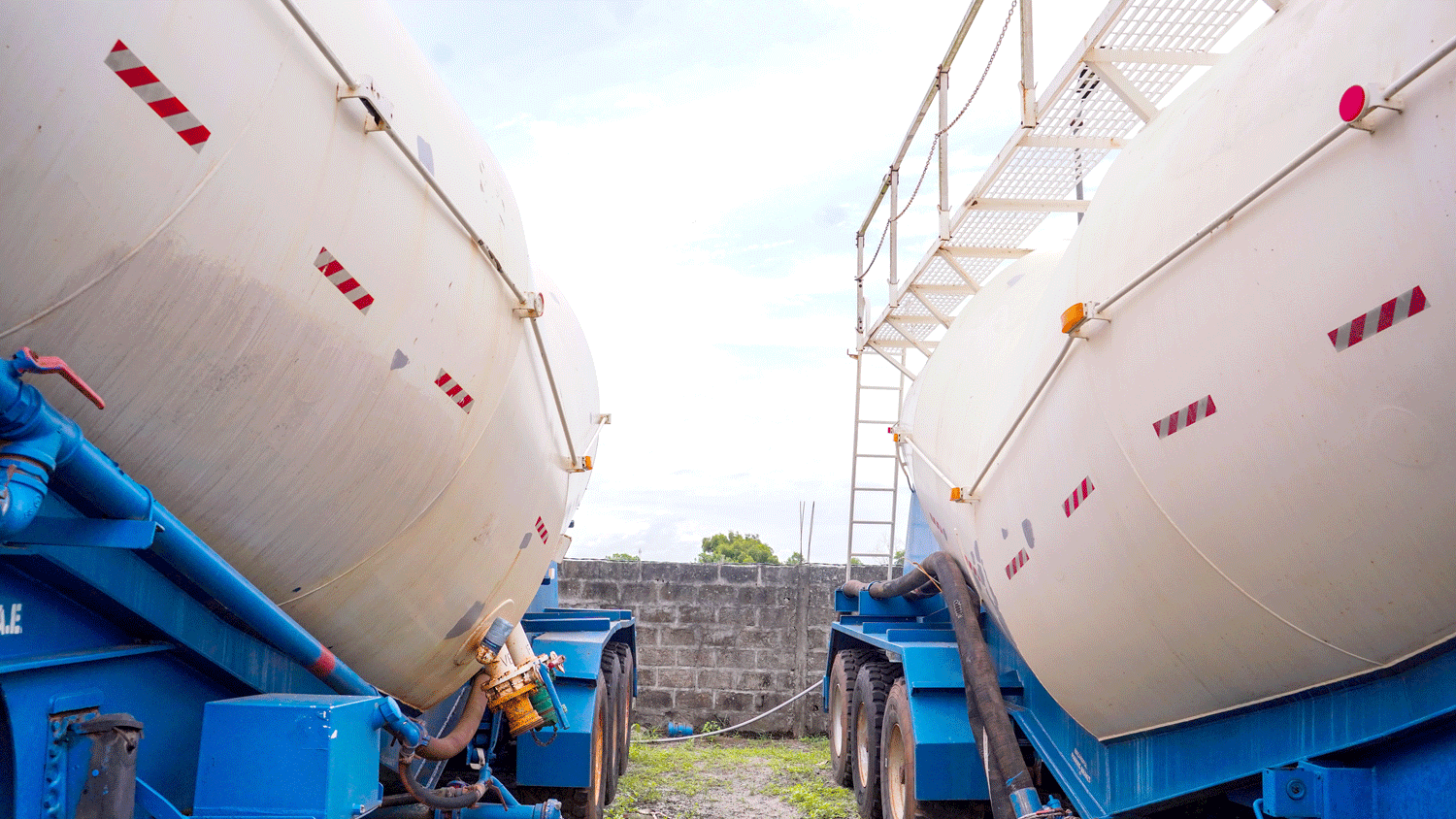

▪ Bulk operations

▪ Lab testing

Executive Management

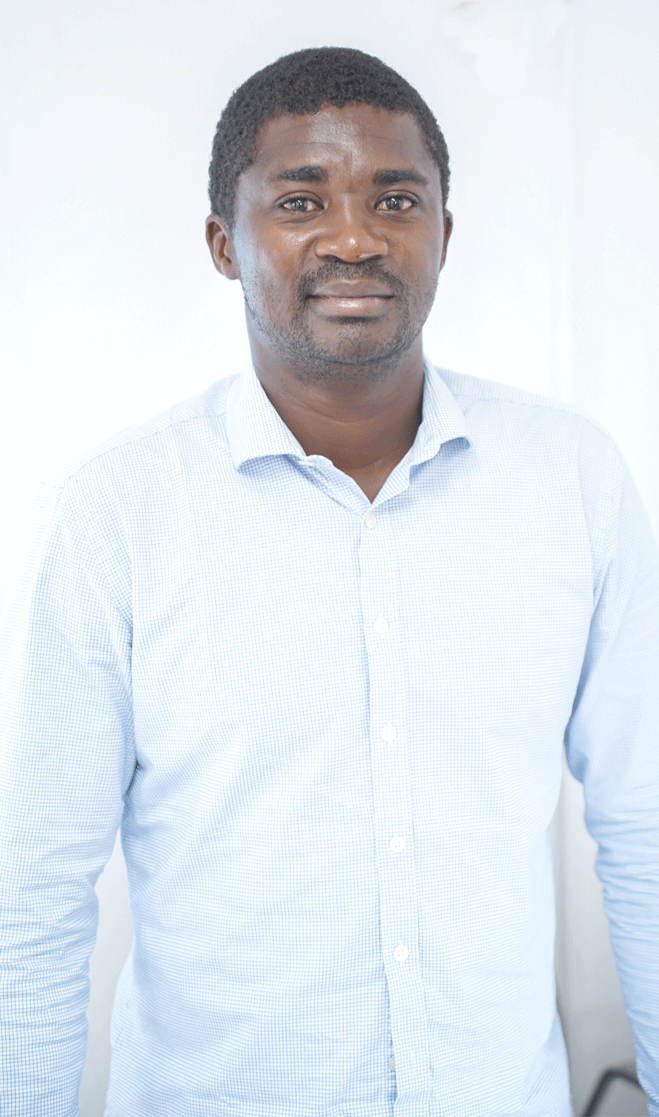

Felix MOUSSIMA

- Over 27 years of Oil Industry experience with deep knowledge of operations, finance, tax and accounting

- FAET Manager Since Nov 2021

- Drill-Watt General Manager (since 2012)

- Drill-Watt Financial Controller (since 2011)

- Schlumberger Controller Gabon Oilfield Services (2007 to 2010)

- Schlumberger Regional Controller for three (3) product lines (Well Services including cementing and pumping services / IPM and OFS) based in Luanda/Douala allocated in the following countries: Angola, South Africa, Congo, Gabon, Cameroon, Ivory Coast, Ghana and Chad (2004 to 2006).

- Various global roles within Schlumberger from 1996 to 2003.

Felix MOUSSIMA

- Over 27 years of Oil Industry experience with deep knowledge of operations, finance, tax and accounting

- FAET Manager Since Nov 2021

- Drill-Watt General Manager (since 2012)

- Drill-Watt Financial Controller (since 2011)

- Schlumberger Controller Gabon Oilfield Services (2007 to 2010)

- Schlumberger Regional Controller for three (3) product lines (Well Services including cementing and pumping services / IPM and OFS) based in Luanda/Douala allocated in the following countries: Angola, South Africa, Congo, Gabon, Cameroon, Ivory Coast, Ghana and Chad (2004 to 2006).

- Various global roles within Schlumberger from 1996 to 2003.

Felix MOUSSIMA

- Over 27 years of Oil Industry experience with deep knowledge of operations, finance, tax and accounting

- FAET Manager Since Nov 2021

- Drill-Watt General Manager (since 2012)

- Drill-Watt Financial Controller (since 2011)

- Schlumberger Controller Gabon Oilfield Services (2007 to 2010)

- Schlumberger Regional Controller for three (3) product lines (Well Services including cementing and pumping services / IPM and OFS) based in Luanda/Douala allocated in the following countries: Angola, South Africa, Congo, Gabon, Cameroon, Ivory Coast, Ghana and Chad (2004 to 2006).

- Various global roles within Schlumberger from 1996 to 2003.

A truly Local Content Provider

Paul Ndong Beka III is Gabonese acting FAET Gabon Ltd Field Service Manager, a position held since October 1ST, 2024. Main responsibilities include cementing operations management, Sales & Commercial, Business development.

Prior to this role, he was a SLB employee as Customer Engagement Coordinator. These roles spanned technical and sales, line management, operations integrity, field operations and resource planning, Assets and chemicals inventory management. Paul is a highly skilled Ex-SLB Design Engineer with over 09 years experience in oilfield.

Paul holds an engineer degree in civil engineering from Masuku Polytechnical School in Gabon, and a master degree in Petroleum Engineering from Oil and Gas Institute of Monastir (OGIM) in Tunisia.

Paul BEKA

SOME FAET EQUIPMENTS

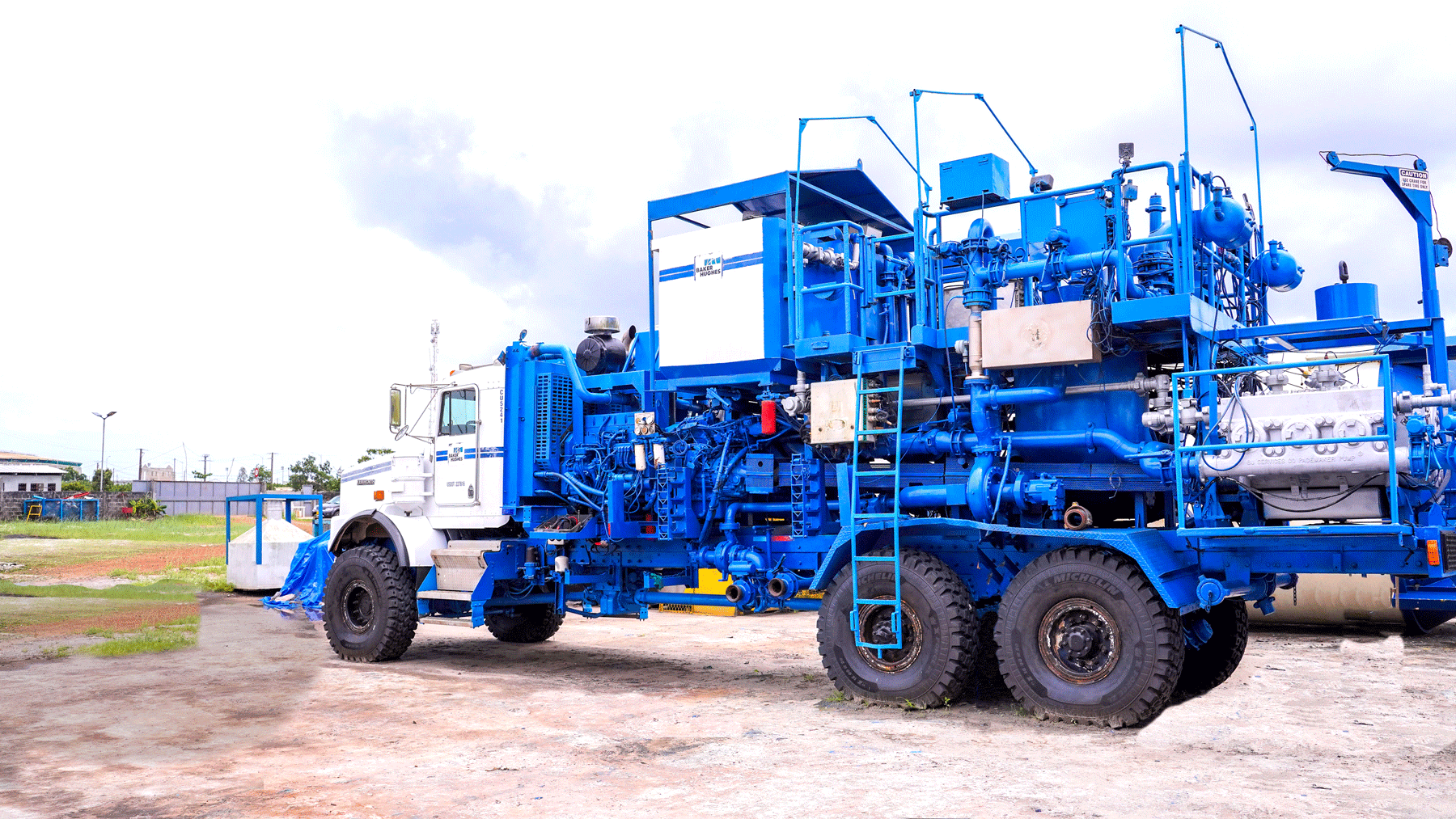

TUCANO Truck Unit Overview

Applications :

▪ Land cement pumping operations.

Benefits :

▪ Minimizes nonproductive time with reliable twin-pump design.

▪ Minimizes slurry consistency risks by precisely controlling its density.

he self-contained, chassis mounted Tucano cement mixing and pumping unit includes an integral de-aerating mixing

system that accurately maintains slurry density and consistency over a wide range of performance requirements. This twin-pump unit is equipped with latest control and monitoring systems for precise control of job parameters, real-time job data acquisition, and post-job analysis. To ensure successful completion of a job in the event of a component failure, backup systems are provided for the hydraulic system,electronic system and drivet rain.

TUCANO Features

The FAET Services Tucano Cementing Unit is a dual cement pumping unit mounted on a Kenworth 6×6 truck chassis. This unit has been designed with safety, reliability, and accurate job completion in mind. Redundant critical components, such as the hydraulic pumps, mix water pumps and triplex pumps, with independent drive systems ensure successful completion of the job by providing back-up. Backup manual mixing controls are also provided.

The Tucano unit is rated at 650 total HHP, and is equipped with two 446 BHP @ 1800 RPM Cummins QSM-ll in-line six cylinder diesel engines driving BJ Pacemaker triplex plunger pumps (PMP) through Allison HT-750-DRD power shift automatic transmissions. The unit will develop working pressures up to 15,000 psi for standard service. Actual performance is dependent on fluid end and plunger size selection.

The Tucano utilizes an integral Lightning Averaging recirculating Mixing system (LAM). The system provides a dust free environment, minimizes air entrainment, and delivers a homogeneous slurry. An integrated deareator removes transport air from the slurry before it enters the mixing tub The unit is equipped with a BJ Services MCM-2000 to control, monitor and record job parameters for on line and post job analysis. The system provides precise density control and slurry consistency over a wide range of slurry weights and is capable of mixing to within +/- .1 PPG. A mass flowmeter is used to monitor both slurry density and downhole rate. The Tucano offers a wide range of mixing rates which are dependent on the slurry density. Slurry rates have been achieved as high as 12 BPM and densities up to 22 PPG

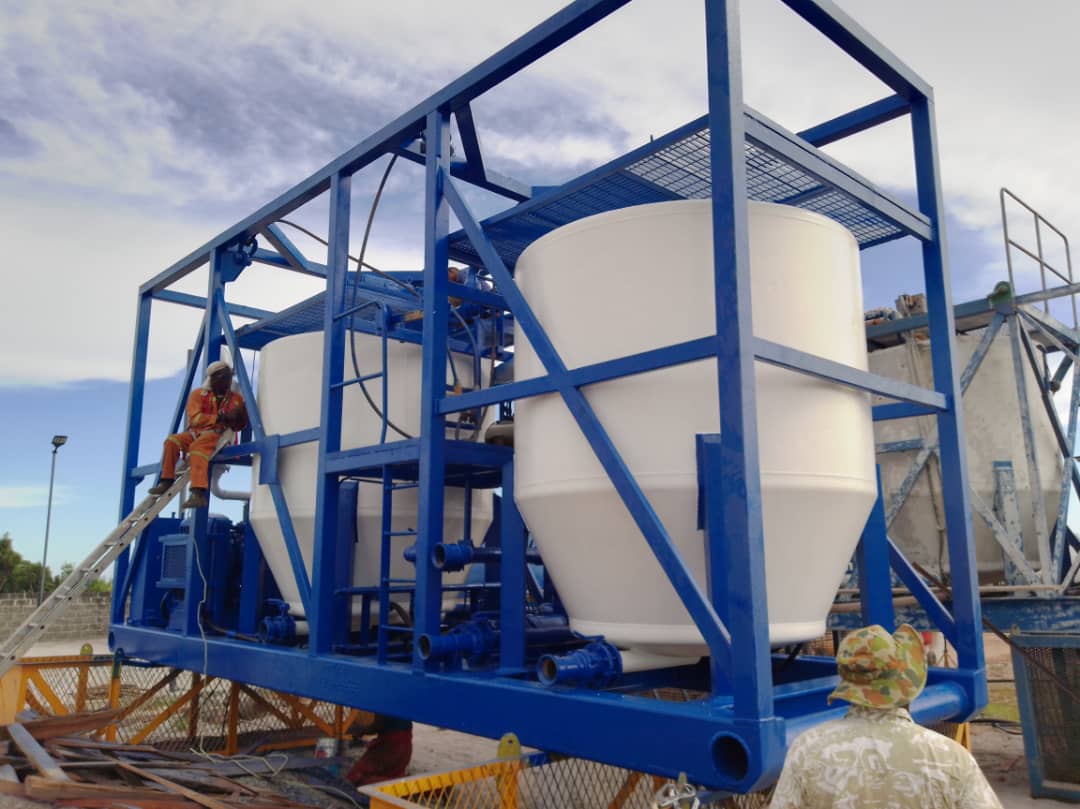

RAM Skid Unit Overview

Applications :

▪ Land and offshore cement pumping

Benefits :

▪ Automatic Density Control System is available as an option. This system is a state of the art system that will constantly maintain the slurry density being pumped downhole.

A choice of downhole densimeters is also available as an option.

A DBIV electronic densimeter is available and it measures slurry density as it enters the Pacemaker pump. A nuclear densimeter is available and it mounts on the discharge of the Pacemaker pump. The BJ 3305 Mini Monitor will continuously monitor, display, and record the density using either densimeter (or the mixing densimeter, if downhole densimeter is not supplied).

RAM General description

The Services Model SCP-40752/RAM (Recirculating Averaging Mixer) is an electric powered skid mounted cement mixing and pumping unit utilizing the patented integral Recirculating Averaging Mixer (RAM) equipped with a BJ Services Mini Monitor (3305) that monitors and records pertinent job parameters for on-line and post job analysis. The main skid can be divided into five (5) separate sections to simplify installation on offshore drilling equipment. There is a separate skid for the mixing water pumps and another skid for the hydraulic power unit.

The unit is rated at 1092 HHP and is equipped with two 900 HP series wound electric traction motors driving BJ Pacemaker triplex plunger pumps through Fuller AT-1202 2 speed twin countershaft transmissions. The unit is capable of working pressures up to 15,000 PSI. Actual performance is dependent on fluid end and plunger size selection.

The RAM is a mixing system that provides density control and slurry consistency over a wide range of slurry weights and capable of mixing to within :to. 1 PPG. This system allows the option of continuous or batch mixing processes. The cement slurry is initially mixed in the mixing module, then passes into the 4 1/2 BBL primary tub for additional mixing. At this point, it flows over a weir into the 20 1/2 BBL secondary tub, where it is mixed further by the agitator, and continuously recirculated until the desired density is achieved. The system provides a dust free environment, minimizes air entrainment, and delivers a homogeneous slurry. A Bl electronic load cell DBIV densimeter is used to monitor the mixing density with an optional DBIV or radioactive densimeter for monitoring and registering the downhole density. The RAM offers a wide range of mixing rates which are dependent on the slurry density. Slurry rates have been achieved as high as 12 BPM and densities up to 22 PPG.

LAB Container

Standalone FAET laboratory for testing as per API standards, current fleet includes :

- Pressurized consistometer (3)

- Atmospheric consistometer (1)

- Electronic balance (2)

- Rheometer (2)

- Constant speed mixer (1)

- Chiller (1)

- Stirred Fluid Loss Cell (1)

- Stirrer (1)

- Pressurized mud balance (1)

- Non-Pressurized mud balance (2)

Nisl massa, ultrices vitae ornare sit amet, ultricies eget orci.